My Work

Explore my Qualifications and Personal Projects

Qualifications

-

University of Washington Class of 2017, Bachelors of Science in Mechanical Engineering (BSME). Cumulative GPA 3.32

-

3+ years of Technical Program Management experience in high volume manufacturing / consumer electronics at Apple.

-

TPM Lead of Apple Watch Ultra 3

-

TPM supporting Apple Watch: Ultra 2, Series 8 and 2024 iPad Air/Pro

-

Handled all TPM cross functional responsibilities including:

-

Process & assembly definition

-

Design for manufacturing & influencing product design for high volume manufacturing

-

Tooling/fixture design (both manual and automated fixture designs, including sensors, PLCs, vision systems, station logic / acceptance criteria, and more)

-

Lean analysis & line balancing, physical space calculations

-

Cost calculations for business discussions, Capex, ROI analysis

-

Root cause / corrective action analysis deep dives

-

Factory line walks/station audits

-

Updates to senior leadership on product health metrics

-

CpK/GRR/DOE data collection to verify process / design / material acceptability

-

Data analytics skillset utilizing JMP and other tools to summarize & visualize key data for cross functional discussions.

-

-

Additionally drove several non-key TPM projects like:

-

Reducing plastic waste on test line to assist with carbon neutral targets

-

Conceptualization to completion full stack software development of a new data analytics app (Javascript/React/CSS, Python, FastAPI, SQLite, PostgreSQL, Electron)

-

Initial version was created by me with Python-only script, later adapted to full stack MacOS application utilizing AI/LLM tools (Gemini, Claude Code) to assist with code generation.

-

Learned:

-

VSCode

-

Git/Github

-

Full stack software architecture

-

Database integration

-

Full scale deployment (software signing, notarization, packaging & distribution hurdles for applications, authentication, automatic updates, etc.)

-

AI/LLM usage, prompt engineering & context management

-

-

-

-

Mentored several other TPMs and Interns on their projects/work/scope and supported their development on the team.

-

Traveled several times for recruiting and hosted numerous interviews for both full time and Intern candidates on our team.

-

Developed novel assembly & fixture qualification methods to support challenging new design to enable Satellite SOS feature in Apple Watch Ultra 3

-

4.5 years of mechanical design experience in aerospace at Honeywell Aerospace.

-

Handled various mechanical design projects for sensors for aerospace applications including:

-

Tooling design (engineering and production) including DFx, GD&T, RFQs and PO placement, design verification testing and fit checks, etc.

-

Finite element analysis (structural, modal, thermal) on all sensor geometries through R&D phases.

-

Project engineering/CAM/CapEx projects

-

Owned capital test station installation on $250k test station

-

Drove all related hardware procurement

-

Vendor and timeline management

-

Station cable definition

-

Data acquisition system definition

-

Cross functional team management

-

-

Systems/Test engineering projects, including:

-

Test environment design for $1B program

-

Test station selection (shock, vibration)

-

Test profile definition (thermal, shock, vibration, centrifuge, calibration)

-

Error Allocation Budget / Requirements Flow-down

-

-

-

Managed capital and non-capital projects in small team settings

-

Completed several MATLAB projects to examine:

-

Allan Variance

-

Misalignment analysis and Tolerance stack-ups in complex systems

-

Examined/proved a failure mode through a first-principles approach with second order ODEs in Matlab, solving a long-standing error-source seen in testing.

-

-

Completed Six Sigma/Lean Manufacturing "Green Belt" Certification

-

Completed PMP Academy, Project Engineering/Program Management Certification

-

-

3 years of experience in Formula SAE, a student led program at the University of Washington where students design and build a fully functional formula one styled vehicle to compete nationally and internationally.

-

Assisted with manufacturing and machining of parts for the car as well as jigging and tooling fixtures

-

Owned design and layup of carbon fiber internal structure for rear and front wings in aero package as well as machining of aluminum 'spars'

-

Owned design of cooling system for 2017 combustion car including radiator, ducting, aero 'pods' to reduce drag around cooling system, fan sizing, and system placement/streamlining.

-

Sponsorship Lead for the 2017 team, leading a team of 25 other engineers to secure funding, materials, and assistance from various industry leaders to supply all of our carbon fiber, composites, machine shop tools, outsourced machining, high density urethane foam for molds, metals for manufacturing, cash, and more (totaling >$1.5M EOY).

-

Assisted with Cost Report, taking on last minute leadership position at competition in Germany.

-

Assisted with car assembly, technical readiness and compliance through technical inspection, and teardown (post-competition) at competitions in Lincoln, Nebraska and Hockenheim, Germany.

-

-

Graduate of Newberg High School Class of 2013, Valedictorian, GPA 4.0

-

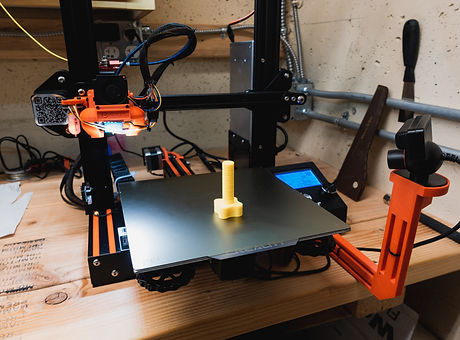

2+ Years of Experience 3D Printing both FDM and SLA style printing and heavily modifying FDM 3D printer. Printed numerous parts for modifications to the printer itself, numerous functional parts to solve minor issues around the house, and numerous prints for fun, as well as now various prints for sale on my Etsy page. Non-exhaustive list of modifications include:

-

Upgraded print bed and leveling springs

-

Upgraded motherboard and re-wired 3D printer

-

Upgraded extruder, nozzle and cooling fan ducts

-

Reduced noise through added damping and heatsinks on motors

-

Added wireless print functionality and control as well as remote viewing via webcam

-

Added LED light kit for improved remote visibility all hours of the day

-

Automated print process through addition of automatic bed leveling - required modification of G-code source code and re-flashing of motherboard as well as significant tuning and setup to properly 'zero' after the initial flash/install.

-

Additional prints to fill 'channels' to prevent plastic buildup from excess plastic.

-

Modifications to extruder housing and printer filament guide to prevent 'catching' in the filament and cable bundles during printing.

-

-

4 years of experience in FIRST Robotics from 2009-2013, assisting in design and assembly as well as testing and debugging of robot during this time. Assisted in logistics and team fundraising efforts both as part of the team as well as individually for my Senior Project - organizing and hosting a 40-person golf tournament with numerous local sponsors that raised over $2500 for the program, allowing for the creation and registration costs for 3 new teams comprised of younger students.

-

Machined and assembled my own fully functional Stirling Engine through the 'Engineering' courses offered during my time in High School.

-

Numerous modifications and routine maintenance performed on personal vehicles, both my Honda Accord and my Suzuki DR200 motorcycle. I have performed regular routine maintenance on these as well as completed larger jobs on both vehicles in order to swap out broken or old components, such as brake pads and rotors, stereo deck swaps, spark plug change, serpentine belt change, air filter changes, hand grip swaps on dirt bike and more.

-

Other skills include:

-

Electronics / Circuit design (some college level coursework and a few personal projects, see custom built LED kit for Dirt Bike and "Star Tracker" 3D print project)

-

Coding:

-

Python (Proficient)

-

HTML/CSS (Intermediate)

-

JavaScript (Intermediate)

-

Matlab (Intermediate)

-

C# (Beginner)

-

Ruby (Beginner)

-

PHP (Beginner)

-

Java (Beginner)

-

Swift (Beginner)

-

Kotlin (Beginner)

-

SQL (Beginner)

-

*All above courses listed as "Beginner" are 100% complete through full Codecademy course, any listed as "Intermediate" involve extra-curricular projects completed outside of that

-

-

-

Fluent in Microsoft Office Suite (Excel, Word, PowerPoint)

-

CREO, Solidworks, Autodesk Inventor

-

AutoCAD

-

ANSYS Workbench, Fluent, APDL

-

Blender/Cinema4D

-

Photoshop/Lightroom

-

Video Editing/VFX (DaVinci Resolve)

-

3 Axis CNC, Lathe, Welding (Arc and Oxy-acetylene), Cutting torch, Router, Bandsaw, Water-Jetting, sheet-metal and sheet-plastic bending (polycarbonate).

-

Soldering (Beginner)

-

-

Learning languages:

-

Spanish (4+ years experience, intermediate understanding, basic verbal fluency)

-

German (1-2 years experience, intermediate understanding, basic verbal fluency)

-

Russian (<1 year experience, beginner understanding, beginner verbal fluency)

-

“Scientists study the world as it is; engineers create the world that has never been.”

Theodore von Karman